📞 1- 888-575-9929 | 💬LIVE CHAT 🛍️WEB STORES 📱 CONTACT US 📜GET A QUOTE 📁UPLOAD ART FAQs

Introducing DTF Transfers at GMB CUSTOM APPAREL

We are excited to announce that we now offer Direct-to-Film (DTF) transfers! This cutting-edge printing technology provides superior quality and durability for all your custom designs. Whether you're looking to create vibrant t-shirts, hats, bags, or any other textile product, our DTF transfers ensure vivid colors and long-lasting prints.

What is DTF (Direct-to-Film) Printing?

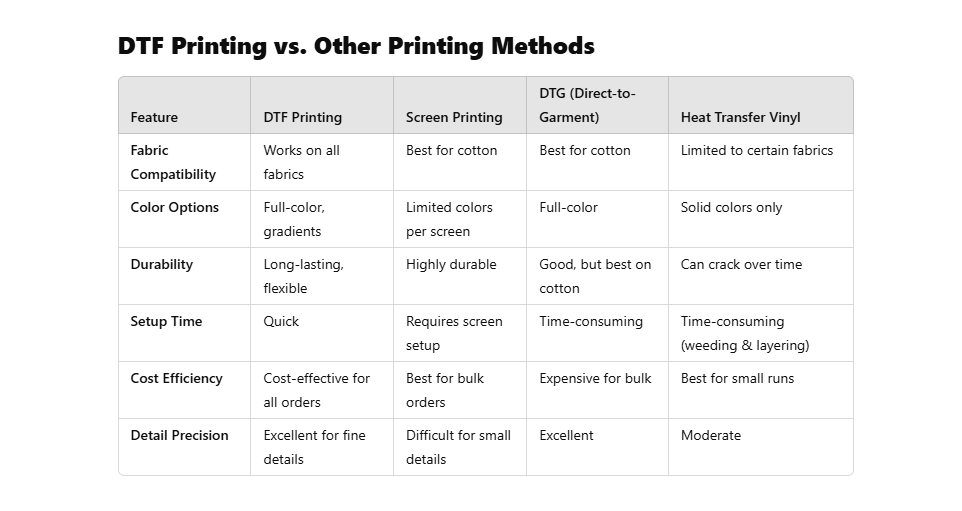

DTF (Direct-to-Film) printing is a revolutionary heat transfer technology that allows for vibrant, high-quality prints on a variety of fabrics. Unlike traditional screen printing or heat transfer vinyl, DTF printing does not require weeding or cutting, making it a faster and more efficient method for producing custom apparel with intricate designs and full-color graphics.

This versatile printing process works on cotton, polyester, blends, and even dark-colored fabrics without the need for pre-treatment. Whether you’re looking for custom t-shirts, hoodies, bags, or promotional apparel, DTF printing ensures crisp, detailed designs with superior durability and washability.

Looking for vibrant, durable, and easy-to-apply DTF transfers?

GMB Custom Apparel has you covered! Whether you're a business, brand, or custom apparel creator, our ready-to-press DTF transfers provide high-definition prints, superior stretchability, and long-lasting durability on any fabric.

Why Choose Our DTF Transfers?

Exceptional Detail

Versatile Application

Durable Prints

Vibrant Colors

Longevity of DTF Printing: How Durable is It?

One of the biggest advantages of DTF (Direct-to-Film) printing is its exceptional durability, especially when compared to traditional heat transfer methods. With proper care, DTF prints can withstand 50+ washes while maintaining their vibrant colors and flexibility.

Unlike screen printing, which can crack over time, or vinyl, which may peel, DTF prints are designed to last. The hot-melt adhesive used in DTF printing bonds deeply with the fabric, ensuring that the design remains intact without fading, cracking, or peeling even after multiple washes.

How to Care for DTF Printed Apparel for Maximum Longevity

To keep your DTF-printed garments looking fresh and vibrant, follow these care instructions:

✔

Wash Inside Out – This minimizes direct friction on the design.

✔

Use Cold Water – Hot water can break down the ink and adhesive faster.

✔

Mild Detergent Only –

Avoid harsh detergents or bleach that can weaken the print.

✔

No Fabric Softeners – These can degrade the adhesive, leading to premature wear.

✔

Air Dry When Possible –

High heat from dryers can weaken the bond over time. If using a dryer, opt for a

low heat setting.

✔

Avoid Ironing Directly on the Print – If necessary, turn the garment inside out and iron on low heat.

By following these simple steps, your DTF-printed apparel will stay vibrant, smooth, and intact for years to come.

Looking for vibrant, durable, and easy-to-apply DTF transfers?

GMB Custom Apparel has you covered! Whether you're a business, brand, or custom apparel creator, our ready-to-press DTF transfers provide high-definition prints, superior stretchability, and long-lasting durability on any fabric.

DTF Printing can be used for the following:

🎽 Custom T-Shirts & Hoodies – Perfect for businesses, events, brands, and personal projects.

🎒 Bags & Accessories – High-quality prints on tote bags, backpacks, and more.

🏀 Sports & Team Uniforms – Vibrant, long-lasting logos and names for sportswear.

👕 Fashion & Streetwear Brands – Unique, full-color prints for trendy apparel designs.

🎁 Corporate & Promotional Items – Custom branding on employee uniforms and giveaways.

How Does DTF Printing Work?

1️⃣ Design Preparation – Your artwork is printed onto a special PET film using high-quality DTF inks.

2️⃣ Powder Application – A hot-melt adhesive powder is applied to the print, ensuring it adheres properly to fabric.

3️⃣ Curing Process – The design is heat cured to activate the adhesive for long-lasting results.

4️⃣ Heat Transfer – The printed film is then pressed onto the garment using a heat press.

5️⃣ Peel & Final Touch – Once cooled, the film is peeled away, leaving a soft, durable, and vibrant print.

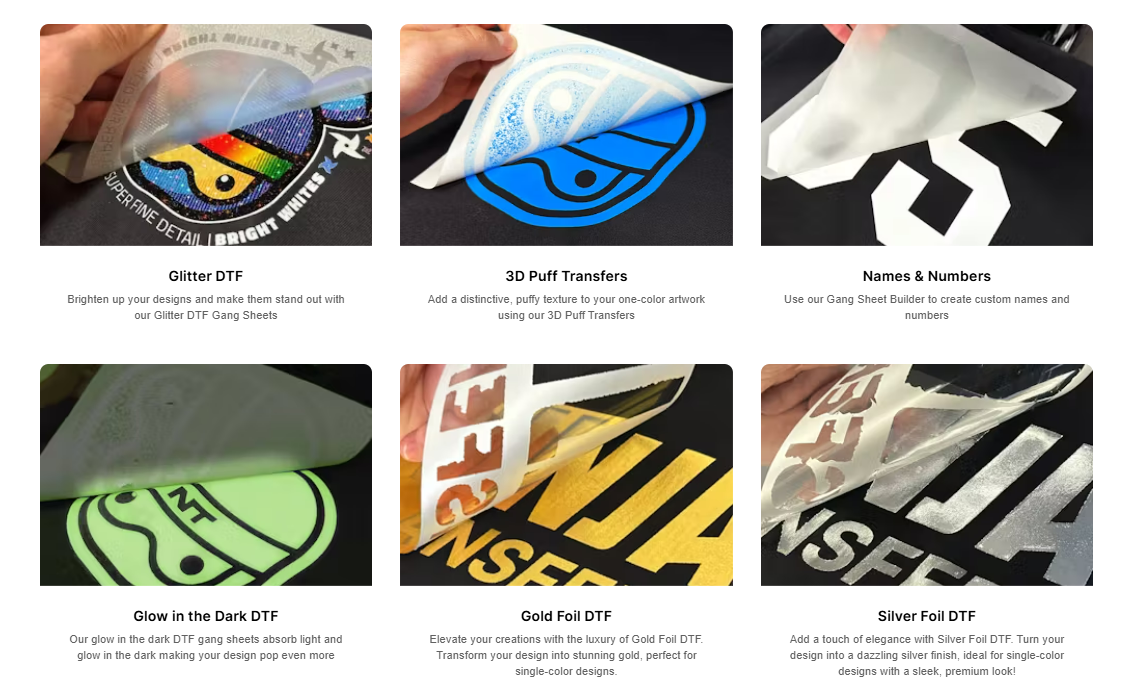

Specialty Transfer Options

What People Say About Us

“Great product. We love working with it!”

MashIt

“Amazing service. Can’t wait to find out what’s next!”

FabuFit

“Not sure what I did before discovering this Product. It’s super!”

YesSuits

Contact us any time

Contact Us

We will get back to you as soon as possible

Please try again later

About GMB

At GMB Custom Apparel, we pride ourselves on being a family-owned business that is deeply passionate about delivering high-quality, stunning designs and creations.

Our commitment is to capture the unique ideas and visions of our customers, ensuring that each item we produce reflects their individual style and personality. We believe in the power of creativity and collaboration, and we strive to turn our customers' dreams into reality with every piece we create.

Quick Links

- Embroidery

- Monogramming

- Screen printing

- Rhinestone services

- Sneaker bedazzling

- Sublimation

- Resources

- FAQ

GET IN TOUCH

Contact us for a quote: